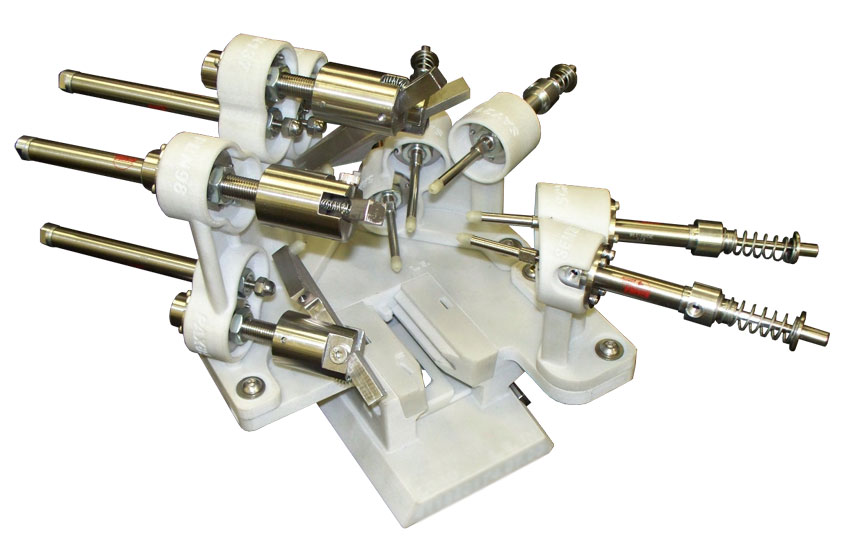

Overview

Quality Engineering has the capability to design and develop low volume prototype SLS (Selective Laser Sintering) tooling for aerospace and commercial parts for a variety of applications. The SLS process is capable of producing snap fits and moving hinges. The approximate maximum dimensions for a single-piece item is: 26″ x 14″ x 21″.

Additionally, the SLA (Stereolithography) parts are produced for fit, form, and function as well as demonstration and show model pieces. The approximate maximum dimensions for a single piece SLA item is: 20″ x 20″ x 20″.

Note: Larger two-piece constructed parts can be produced from both the SLA and SLS processes.